Detecting top of coal

Better detection of the top of coal seam prior to blasting

Accurately detecting the approaching top of a coal seam prior to blasting is fundamental to efficient coal recovery. Previous investigations by member mining companies reported a reduction in coal dilution through disciplined and detailed overburden drilling and blasting practices.

With support from the Australian Coal Association Research Program (ACARP), CRCMining has developed a novel concept for detecting approaching Top of Coal whilst drilling in Rotary Air Blast over-burden blast-hole drilling.

The method of detecting Top of Coal while drilling brings significant benefits to surface mining operations, including:

- Providing a reliable indication of approach to Top of Coal that will enable drilling to be stopped before touching coal or at a minimum standoff distance.

- Increase production by reducing damage to coal from blasting.

- Strata recognition and mapping during routine blast hole drilling.

The project was guided by a steering committee, including appointed industry monitors Kirk Henderson (Peabody Coal), Vishwa Bhushan (RTCA) and Steve Simmons (AAMC). The enthusiastic and generous contribution of both Hughes Drilling and Jellinbah mine which provided assistance, support, equipment and a site for a field trial is acknowledged and greatly appreciated.

The aim of the project is to demonstrate a prototype Measurement While Drilling (MWD) system that can detect approaching Top of Coal while drilling blast holes in a Rotary Air Blast Drill Rig. Benefits of the system are:

- To increase production by reducing damage and dilution to coal from blasting.

- To increase knowledge of overburden strata to inform better blast design.

- To improve productivity, save time and expense of drilling and/or logging holes just to map the top of coal if the same or better information is produced during production drilling.

- To provide information that will assist with drill automation.

- To enable other coal dilution technologies such as blast-hole slotting.

CRCMining project leader Enver Bajram said the ability to detect the approaching Top of Coal seam using MWD system could revolutionise blast hole drilling, leading to a significant reduction in coal loss and dilution.

“The detection system uses resistance measurements ahead of the drill bit to detect approaching coal in real-time whilst drilling. This system can also be retro fitted to a standard rotary air blast drill rig,” Enver said.

“The project has made significant progress by demonstrating the effectiveness of the MWD Top of Coal detection system at mine sites. Preliminary field trials have shown that even with a compromised hardware component, the system is capable of measuring ground resistance while drilling.

“The results from the field trial at Jellinbah mine have also shown that the system was capable of measuring the change in resistance when the drill bit hit coal,” Enver said.

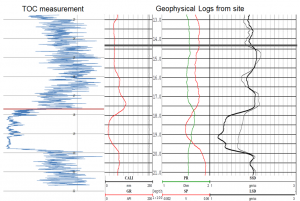

The conventionally acquired geophysical data collected after the field trial correlated well with the Top of Coal system measurements as shown in figure 1 below.

A second field trial is currently being planned with a revised system that addresses the technical issues experienced during the first field trial. The support of Hughes Drilling and Jellinbah mine has been greatly appreciated and enabled effective on-site testing. The second field trial is slated for early May deployment and trials.

Contact: CRCMining project leader Enver Bajram on ph. 07 3365 5637 or e.bajram@crcmining.com.au

Figure 1: Top of Coal systems compared against geophysical logs shows good correlation between TOC measurements and standard geophysical measurements.