Students’ Mining3 semester a great learning experience

Mining3 had the pleasure of working with six outstanding Bachelor of Engineering (Honours)/Master of Engineering (BE (Hons)/ME)* University of Queensland students in the first half of 2018 during their semester-long industry placement—offering them a great opportunity to grow professionally and personally by working alongside and being mentored by experienced researchers on current projects.

One such project was looking at electric autonomous vehicles. Mining3 Program Director, Dr Erik Isokangas, explained these vehicles could potentially haul ore more efficiently than current diesel-powered trucks used by many large mining companies.

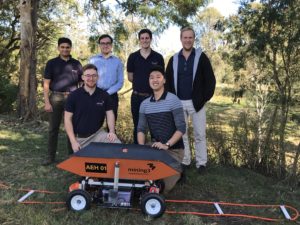

Erik supervised five of the students—Meetkumar Naik, Aaron Birditt, Lachlan Gear, Andrew Osbourne, and Ethan Li—tasking them with creating an electric vehicle prototype requiring continuous charge by a modular and movable electrical induction system.

Mining3 Program Director, Dr Erik Isokangas (rear right); with BE (Hons)/ME students (left to right, back) Meetkumar Naik, Aaron Birditt, and Lachlan Gear, and (front) Andrew Osborne, and Ethan Li, with the proof-of-concept vehicle they built during their semester-long placement with Mining3

Successfully building the proof-of-concept vehicle was a terrific opportunity for the students to not only flex and improve their technical capabilities and problem-solving skills. It also showed them the value of communication, collaboration, and diversity of thought when working with others to transfer a concept to reality.

Erik said it was a challenging task for the students requiring them to design and construct the entire system from the ground up. This presented them with the opportunity to innovate and not be bound by conventional thinking. The students also presented their work and demonstrated the vehicle to Mining3 members during a Technical Committee meeting.

The second project formed part of a Mining3 initiative led by Program Director, Dr Ewan Sellers, to look differently at the way that drilling and explosive loading of blast patterns is conducted.

Ewan supervised student Kohei Usami who worked on a task involving the application of metaheuristic techniques in differential blasting.

Ewan describes differential blasting as a Grade EngineeringTM approach under development by CRC ORE that provides an opportunity for more efficient ore processing in a modern open-pit mine.

The idea is to fragment the ore into fines and the waste coarsely. By sorting the final product only the fine ore is sent to the plant. This considerably increases plant throughput and hence the earning capacity of the mine.

Kohei, an electronics and software engineer student, received a crash-course in mining from Postdoctoral Fellow, Dr Ebrahim Fathi Salmi, and then programmed a Genetic Algorithm based python code to produce optimal differential blast designs that match the fragmentation size to the amount of ore and the rock strength.

A great outcome for Kohei and for Mining3.

Postdoctoral Fellow, Dr Ebrahim Fathi Salmi; Mining3 Program Director, Dr Ewan Sellers; with BE (Hons)/ME student, Kohei Usami

What the students say

The semester at Mining3 has been a great opportunity for professional and personal growth. I gained engineering hard and soft skills beyond anything at university in a Mechatronics project with substantial funding and a solid amount of time. Working at Mining3 provided me with an opportunity to work on cutting-edge research while still being very close to industry itself, through experienced supervisors, industry partners and always ready-to-help co-workers. Meetkumar Naik

My time at Mining3 has been eye-opening and has allowed me to further experience full-time work and develop my engineering skills. As the main contributor to the sensor systems I have been able to advance my technical knowledge in these areas while also learning how a real-world engineering team can operate. Of most value was how Mining3 has helped to expand my professional network by introducing me to a range of industry professionals. Lachlan Gear

Helping develop the mechanical systems on the Autonomous Electric Hauler at Mining3 was a fantastic experience. The project gave me the opportunity to work alongside other Master’s students on a wide-scoped project; one where we were encouraged to harness the knowledge and skills we had learnt at university and effectively address a multi-disciplinary problem. The placement also served as my first glimpse into how a research company operates and an avenue through which I could expand my professional network. Ethan Li

The 24-week placement at Mining3 has provided me with many opportunities for learning. Technically, using my computer and software skills to work towards a potential solution for differential blasting has been rewarding and, although challenging at first, learning about the fundamentals of the mining process has been very interesting. The placement has also provided me with an opportunity to learn how projects are worked on and completed in industry. Kohei Usami

*The University of Queensland’s BE (Hons)/ME program folds undergraduate and postgraduate studies into one unique double degree and includes the defining activity of a full-time placement with industry or a research institution. For more information about the degree, visit www.eait.uq.edu.au/be-me

Mining3 is seeking applications from students for future placement opportunities. For more information, email info@minig3.com or talk to the industry placement contact at your university.

Mining3 operates in a diverse local, national and global community, and values the diversity of its staff and student population. We recognise that equity and diversity can bring about innovation, a more effective use of human resources, and ultimately benefits the creative and intellectual life of Mining3 and the wider community.

We encourage women to enquire about and apply to our education activities, and advise that we participate in Women in STEM student placement programs.